The most frequently asked question is what are the faults which can be repaired by a laser machine?

The principle of laser machine is for LCD LED screen inside circuit repairing, that means almost all faults which caused by screen inside circuit are can repaired by a laser machine. And laser machine also can repair some COF/TAB faults (instead of bonding machine).

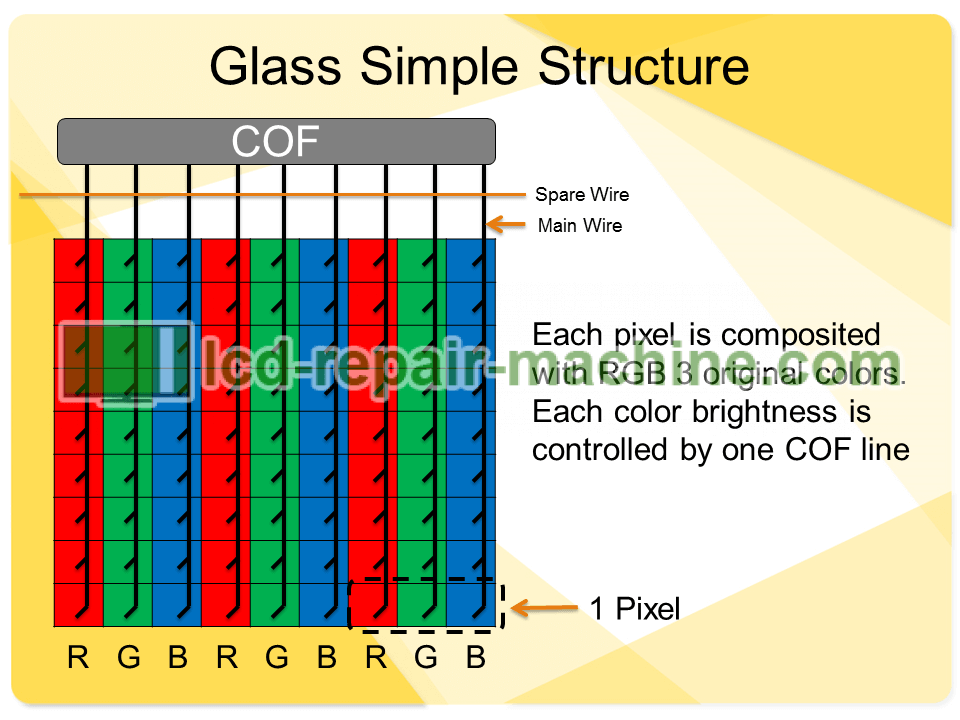

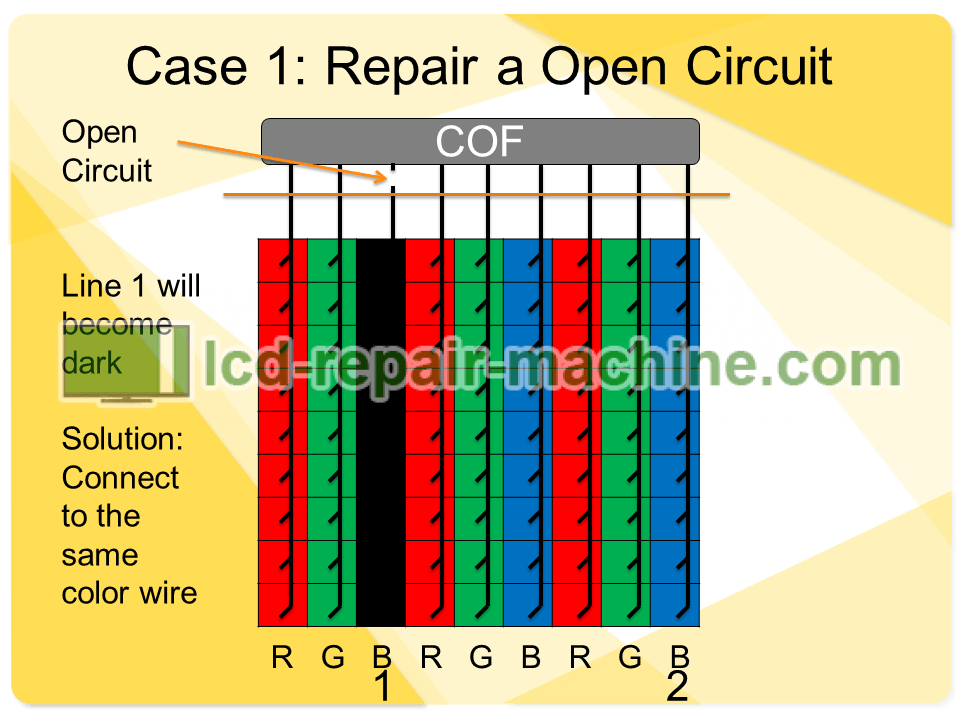

Each pixel is composited with RGB 3 original colors. Each color brightness is controlled by one COF line

The principle of laser machine repairing is using the power of laser to change the circuit connection in glass.

Have two functions:

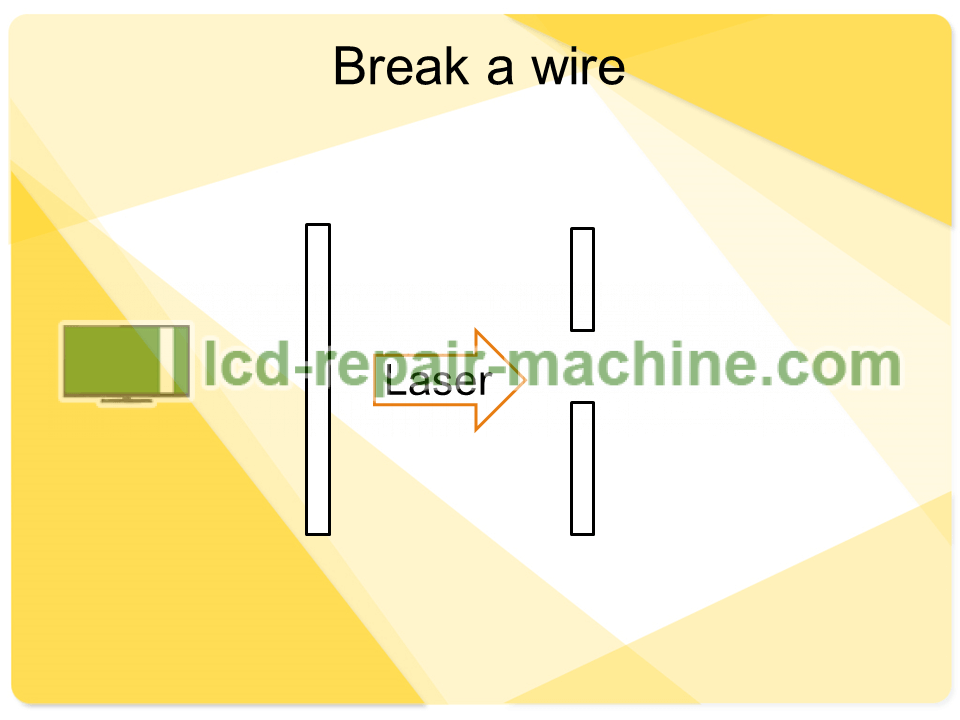

1. Break a wire

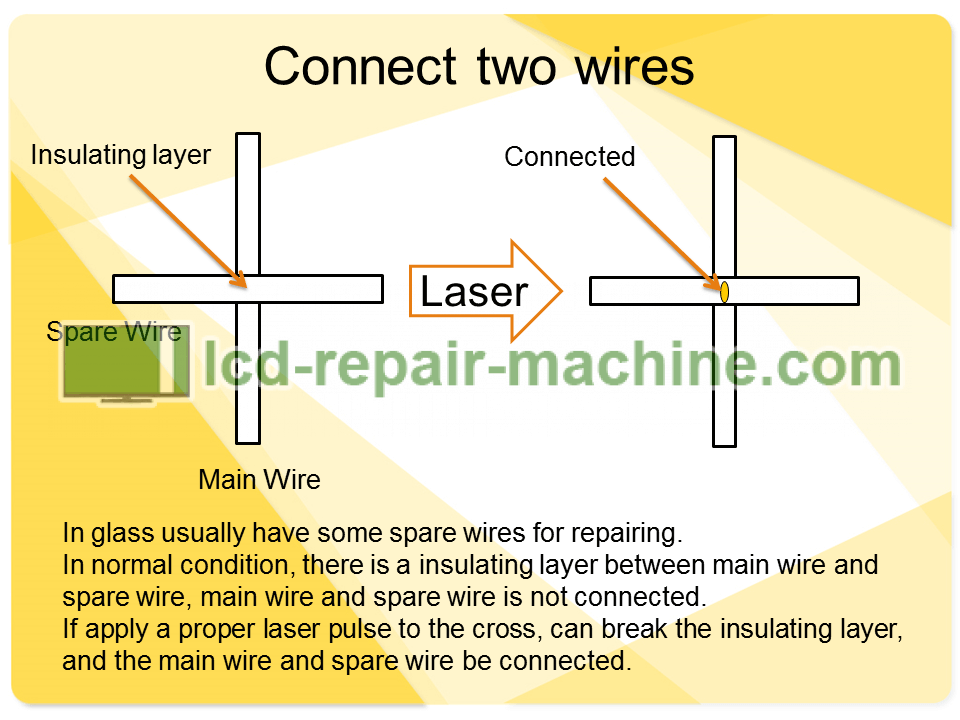

2. Connect two wires

In glass, usually have some spare wires for repairing.

In normal condition, there is a insulating layer between main wire and spare wire, main wire and spare wire is not connected.

If apply a proper laser pulse to the cross, can break the insulating layer, and the main wire and spare wire will be connected.

Solution: Connect to the same color wire

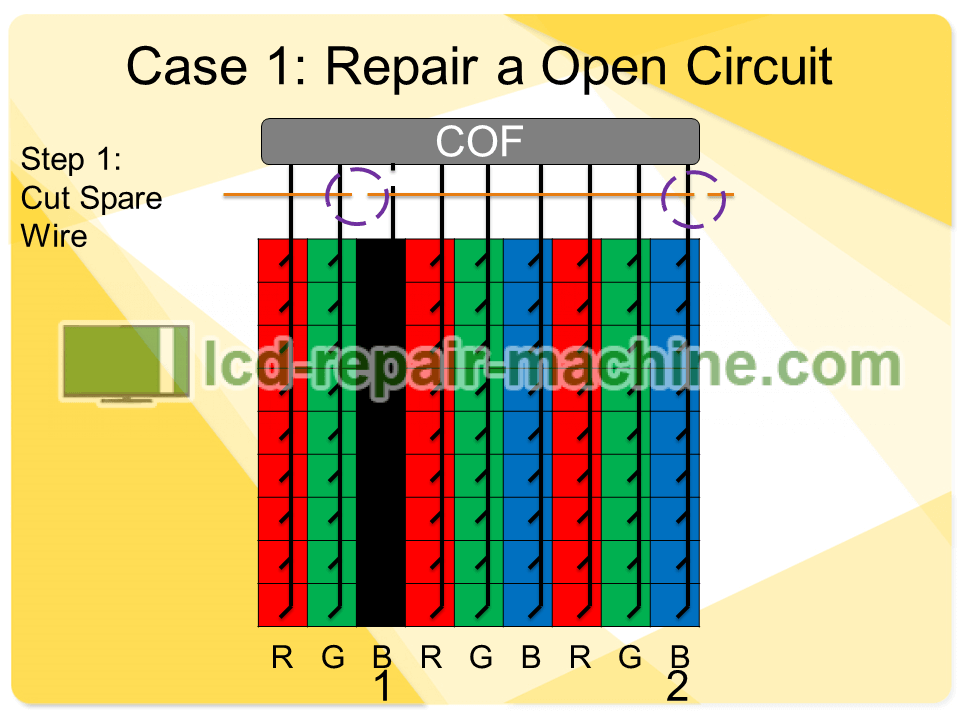

Step 1: Cut spare wire

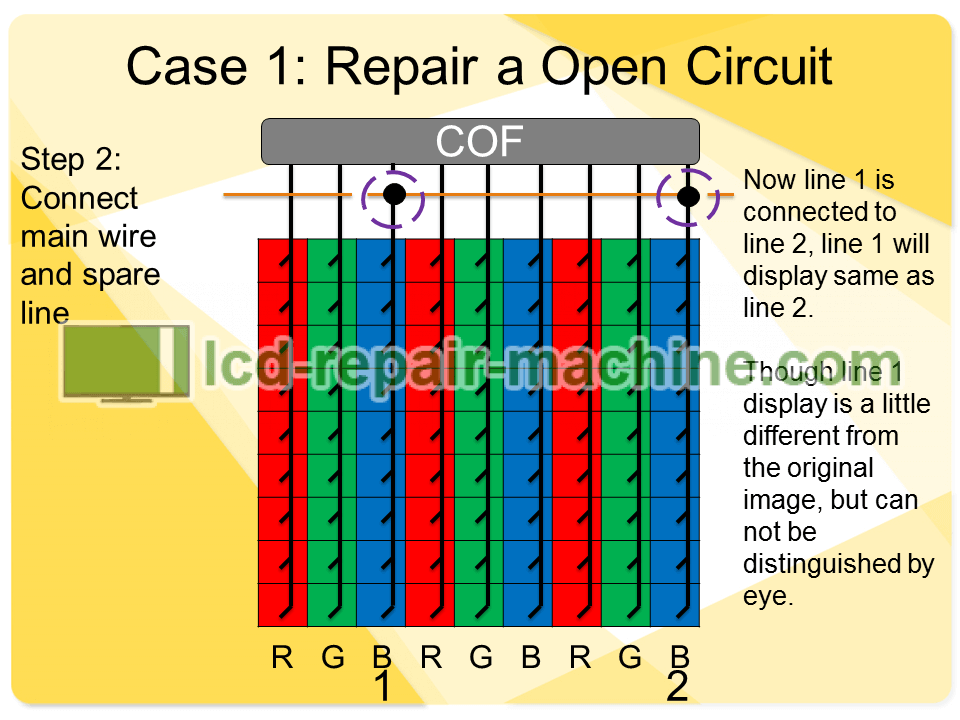

Step 2: Connect main wire and spare wire

Now line 1 is connected to line 2, line will display same as line 2.

Though line 1 display is a little different from the original image, but can not be distinguished by eye.

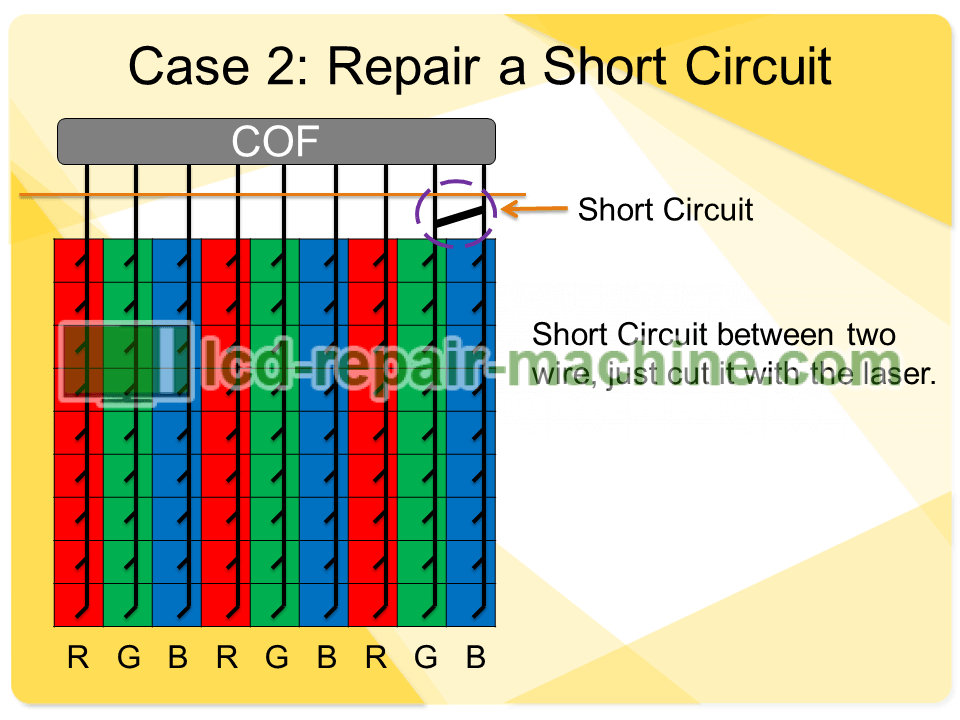

Short circuit between two wires, just cut it with the laser.

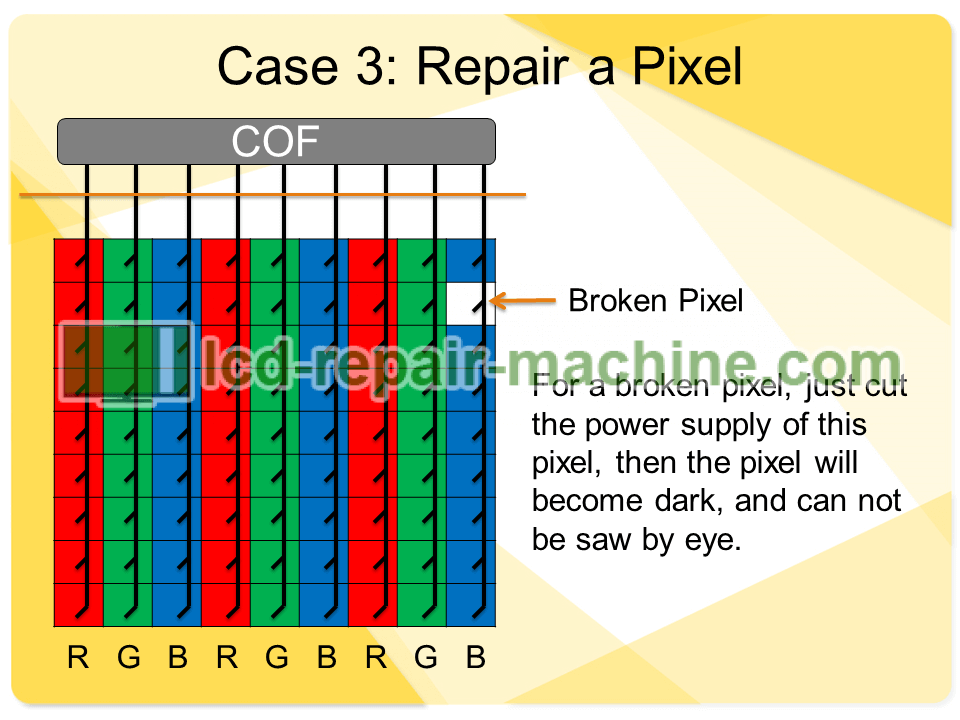

For a broken pixel, just cut the power supply of this pixel, then the the pixel will become dark, and can not be saw by eye.

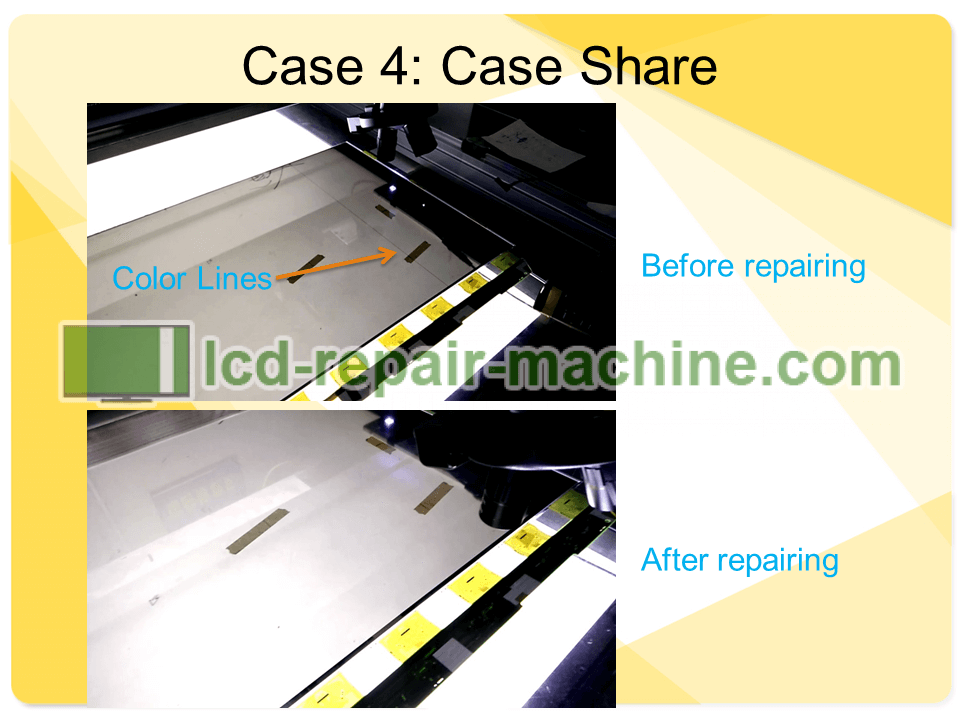

User laser machine to repair a vertical line on LCD LED screen

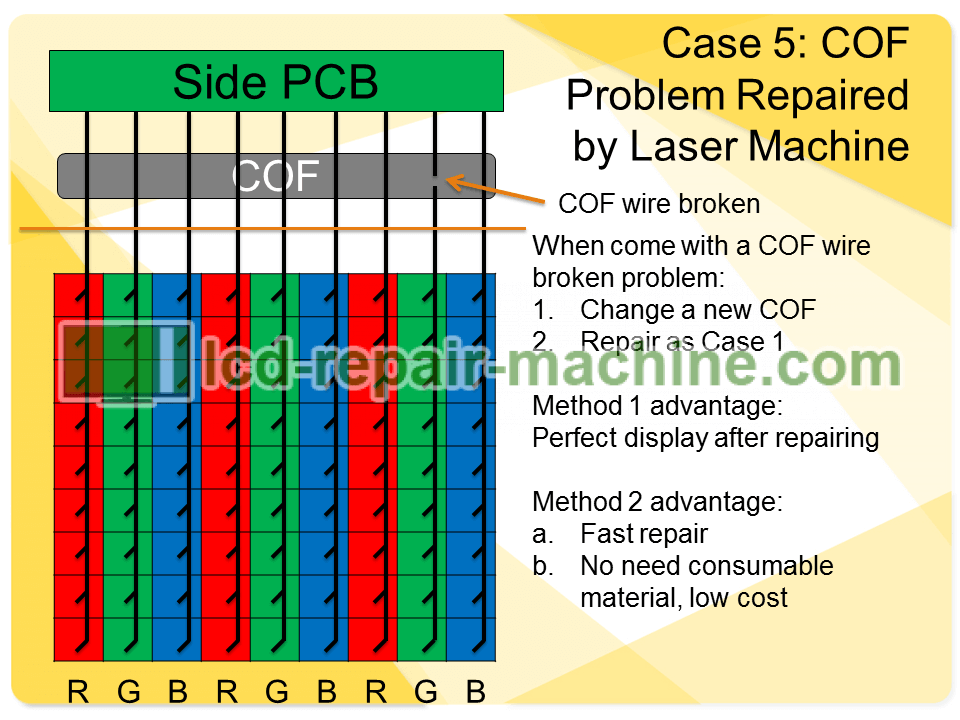

When come with a COF wire broken problem:

1. Change a new COF

2. Repair as Case 1

Method 1 advantage:

Perfect display after repairing

Method 2 advantage:

a. Fast repairing

b. No need consumable material, low cost.

How to Repair a LCD TV with Colored Vertical and Horizontal Lines By a Laser Machine