512DH+ LCD Screen Laser Repair Machine

- General Details

- Specification

- Inquiry

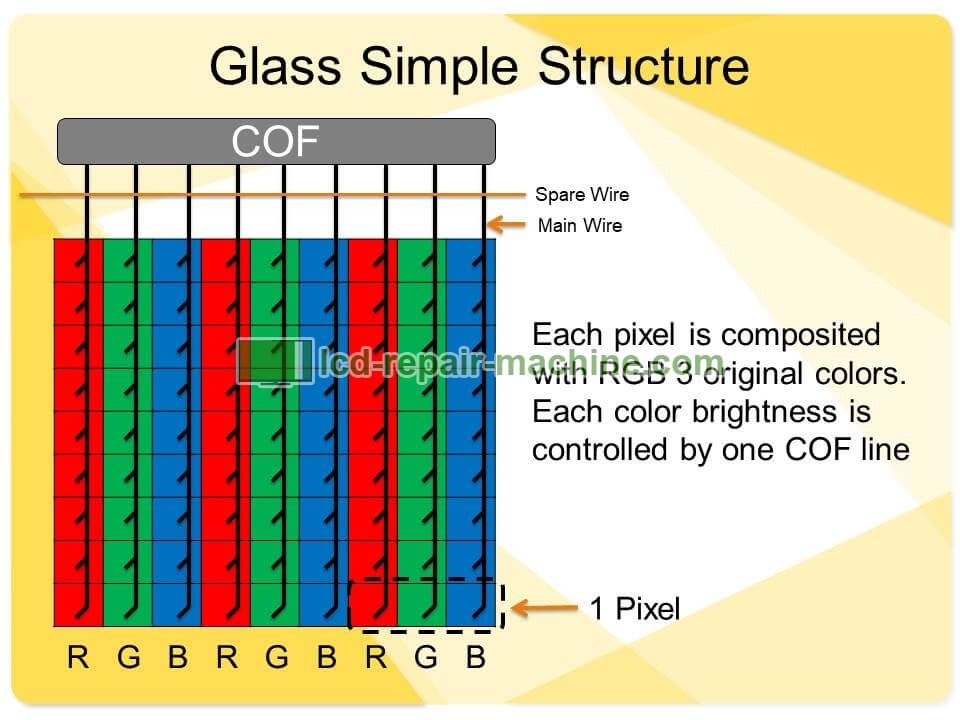

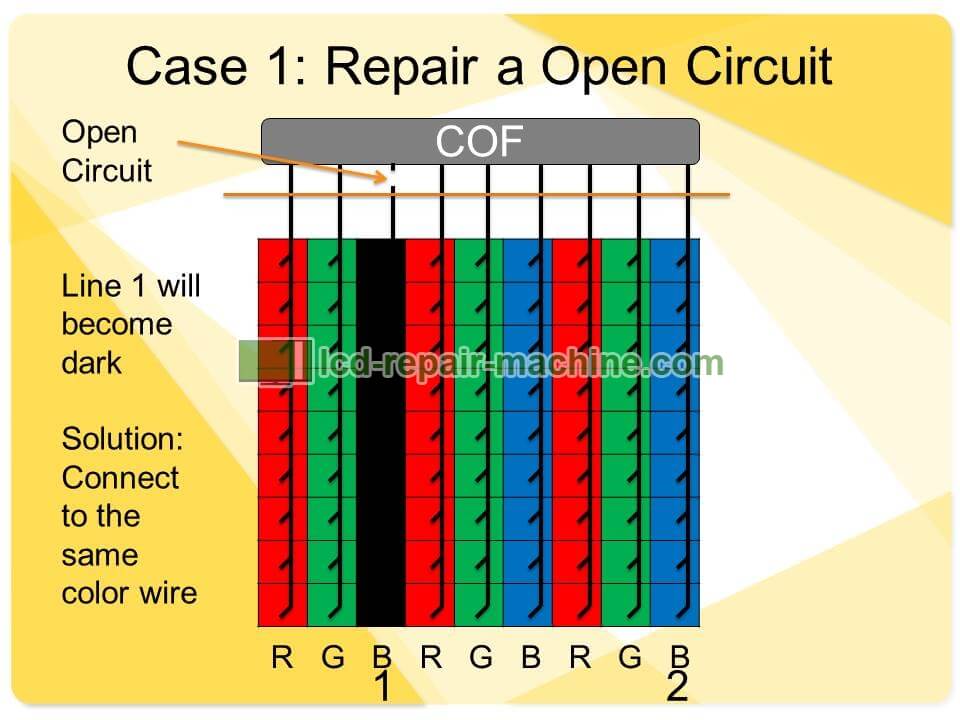

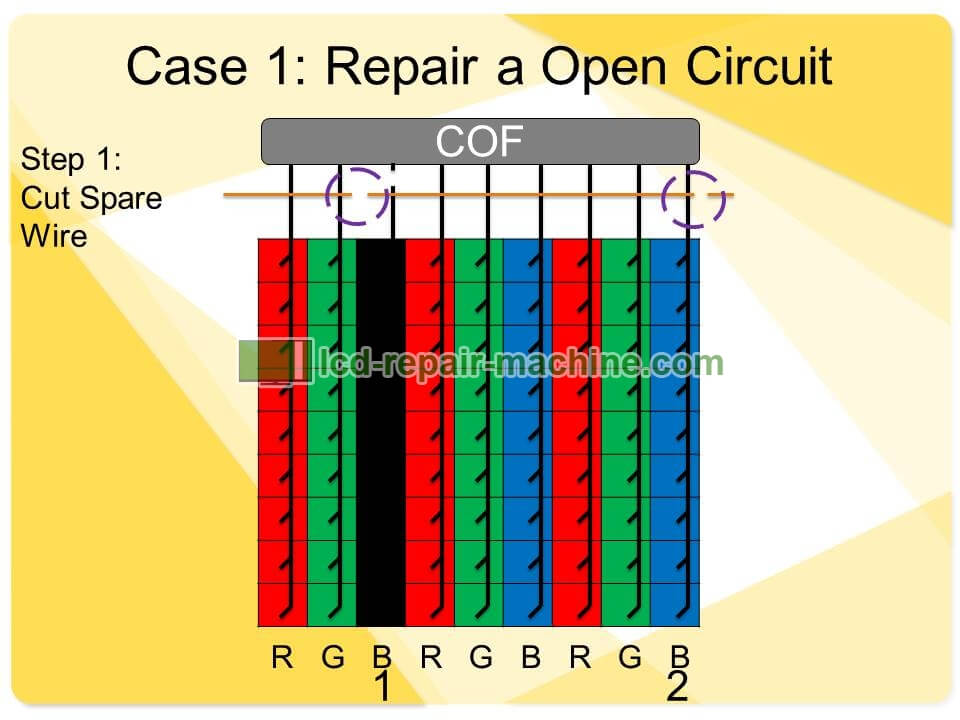

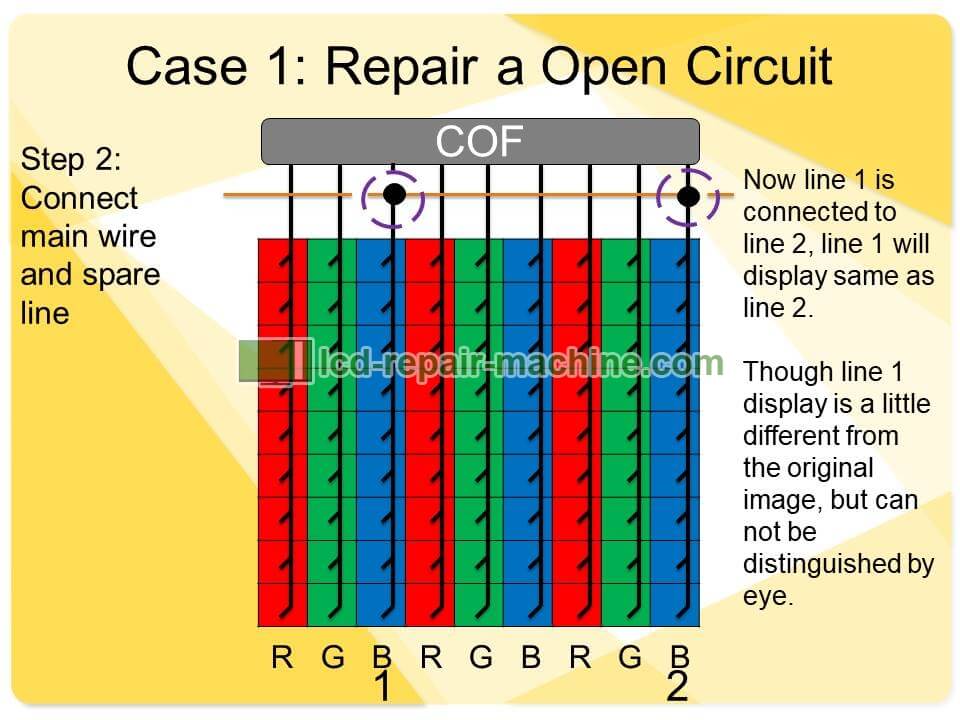

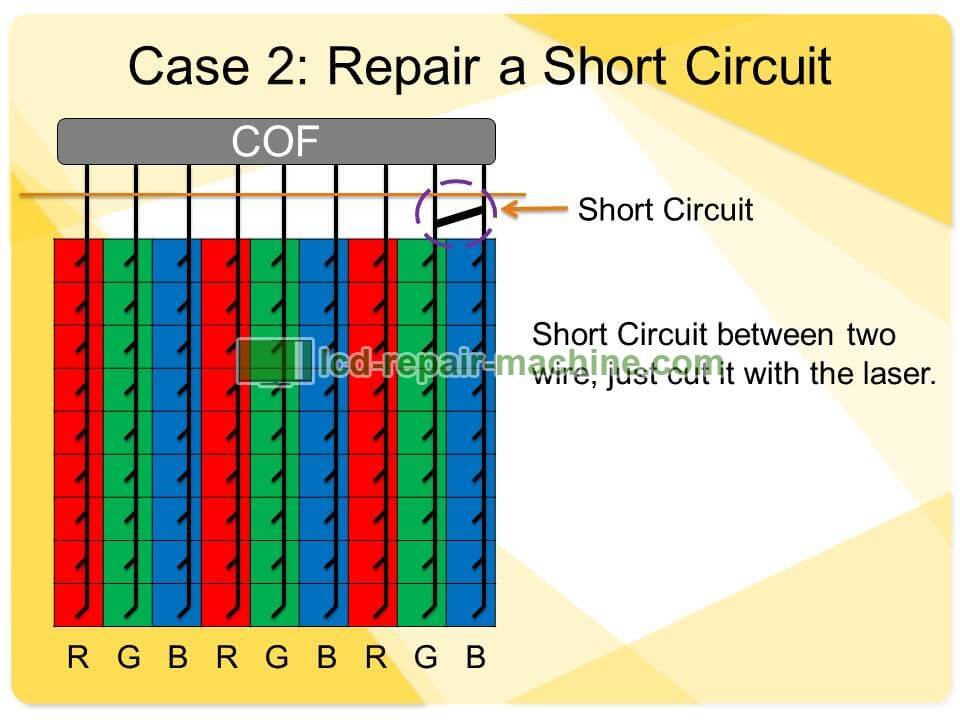

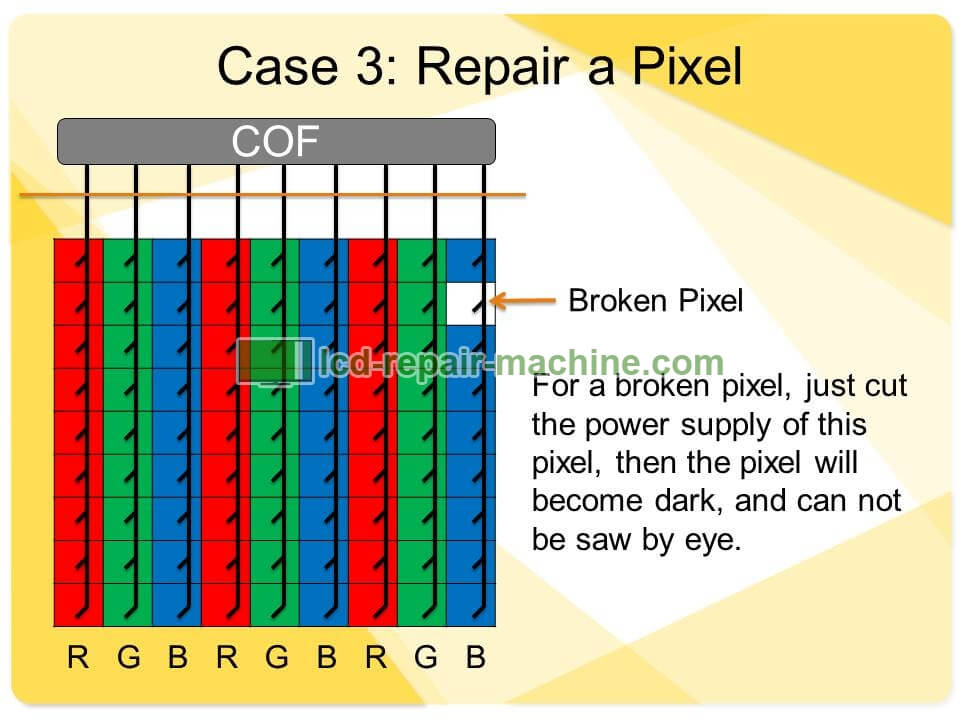

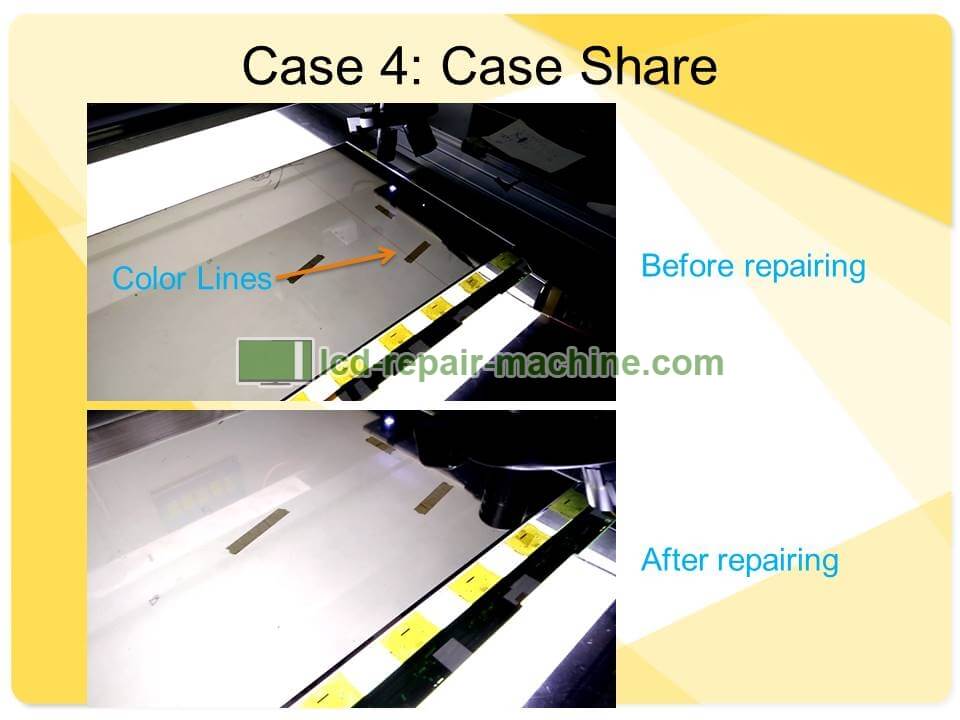

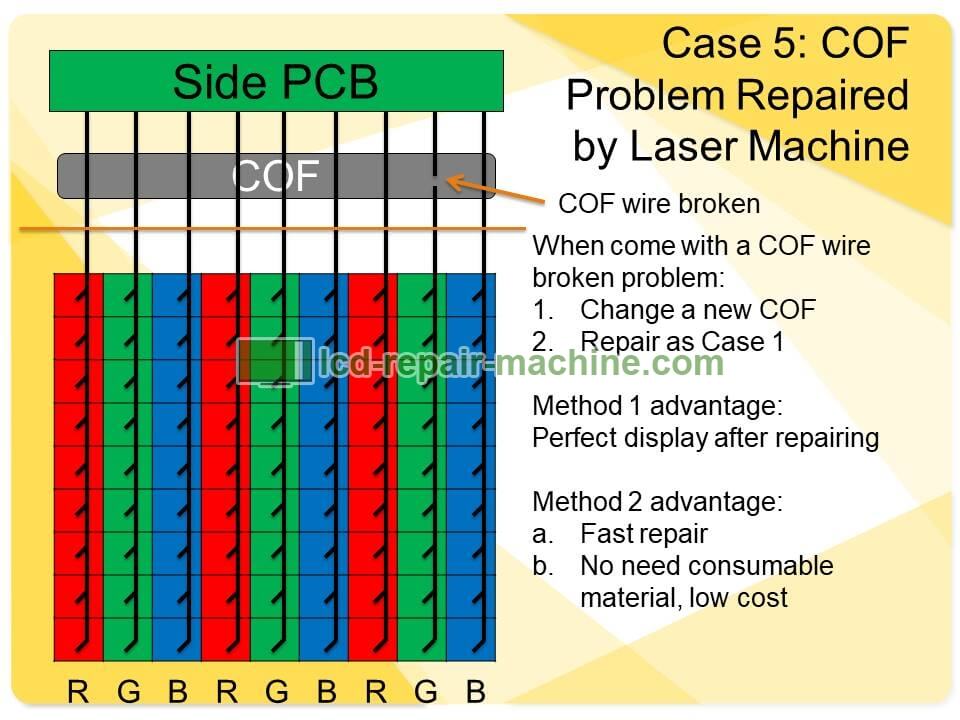

The laser machines are used for various brand of TV repairing; the function of the machine is ITO circuit repairing. Which can solve the problem of COF fault lines, scorching (this problem also can be repaired by a bonding machine), ITO circuit break line, short line, bright line, half-bright line, spot line, multiple line. Laser machine have the advantages of high efficiency, high repair rate, and low cost (no need change parts like COF and other consumable).

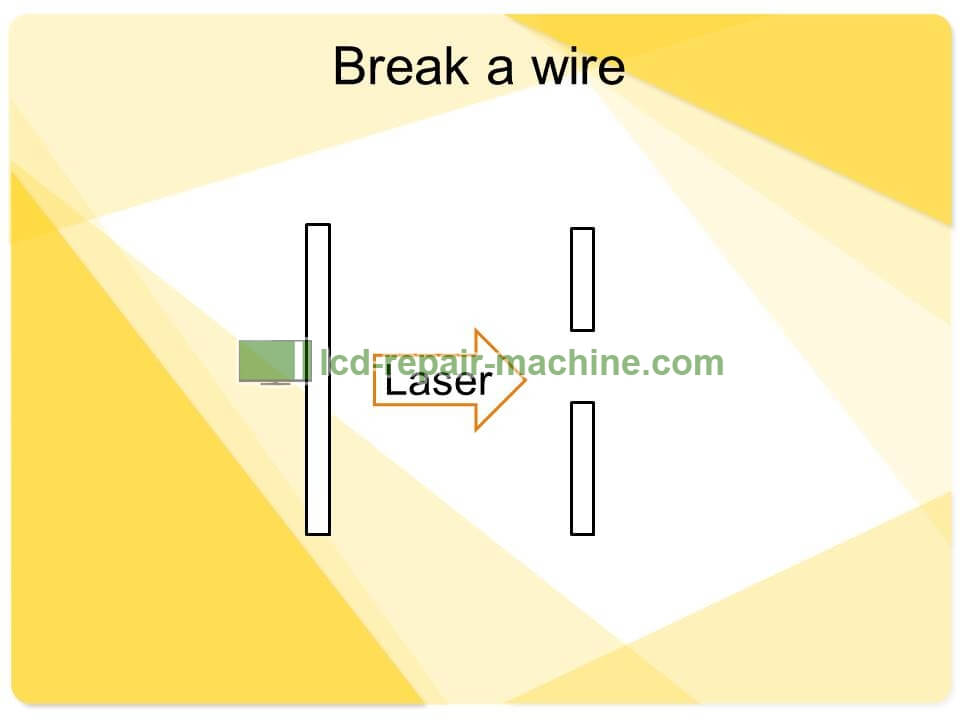

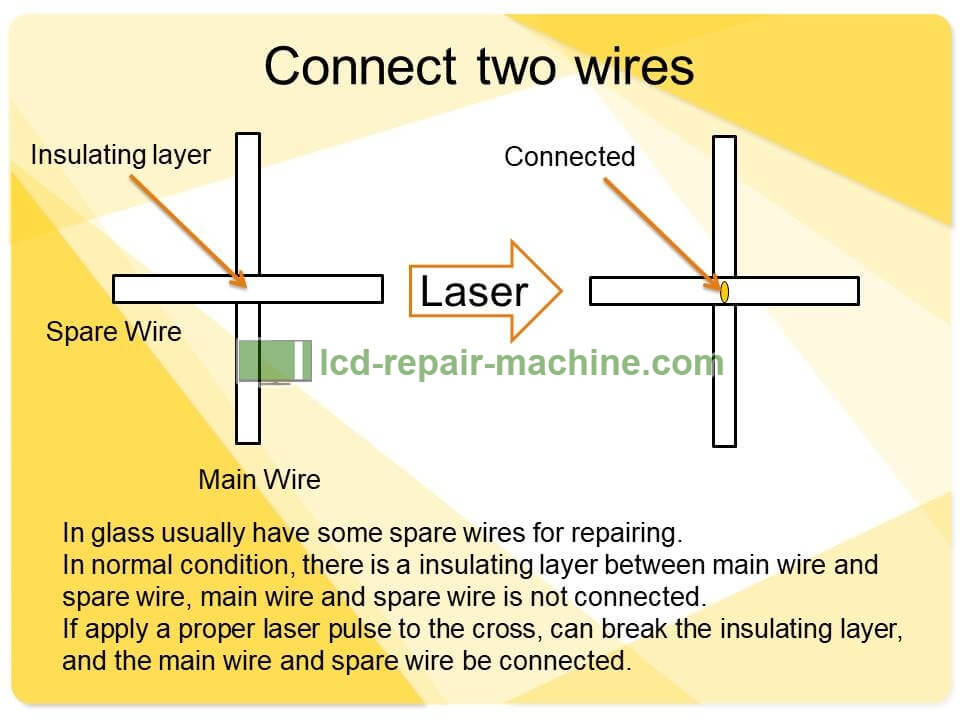

Principle Of Laser Machine ?

LCD screen laser repair equipment parameters

Size:

1660mm×1230mm×1700mm (according to the actual design)

Weight:

450KG

- Applicable LCD panel sizes maximum 50, 100 inches or customized (orbital platform can be expanded)

- Point (3um X 3um), Line (L 50um X 3um), Blocks (50um X 50um) Patch

Repair fog polarizing film of the LCD panel

- Electronic shutter red light and red box dual display

- Shutter size?lens multiplying power and laser power parameters are stored and selection

- Power supply 220V, 30A

- No fuse protection circuit breaker protection

- Operating ambient temperature 20 ? ~ 30 ? + / – 5 ?

- Operating ambient relative humidity65 ±5 ?RH

Laser systems:

Control system from research and development

Type of laser :

ND-YAG LASER

Wavelength :

1064 / 532nm dual wavelength (532nm in order to adjust the wavelength of the optical axis)

532nm wavelength for the adjustment of the optical axis

Way of cooling:

Water-cooled

Laser power:

3?8mJ/Pulse

Oscillation frequency:

1 ~ 20 Hz / sec

Maximum peak power:

1mW

1064 Volatility:

8 ~ 6 nsec

Energy output control:

512steps for 0-100% Hi / Low switch-able

Flash Lamp Life Time:

- 1 year or greater than 1000000 shots

Laser oscillator Warranty:

1 year

The actual laser specification prevail

Processing stage and X/Y/Z-axis drive system

Working platform size:

1250 mm X 900 mm

Stage material:

Grinding optical glass platform

Stage base:

Confidential steel base

X/Y axis effective stroke:

1250 mm X 900 mm

X/Y axis drive form servo motor system X/Y axis drive form servo motor system collocation

X/Y axis minimum resolution:

1um/pulse

Reproducibility:

Less than or equal 5 um

Z axis maximum effective stroke:

100mm

Z axis drive form servo motor system X/Y axis drive form servo motor system collocation confidential screw

Z axis minimum resolution:

0.1um/pulse

In the actual design configuration prevail

Optical Imaging System

Microscope/laser processing special type:

CCD 1/2”color CCD

Episcopic light source:

Halogen light source system of high brightness (100W)

Transmission light source

Halogen light source system of high brightness (150W)

Guide Light :

Halogen light source system of high brightness (100W)

Objective lens switching system 4 holes/Electric switchable type(linear)

Precision lens group 5 times/10 times/20 times/50 times/

(the latter two with observer/laser processing function)

M PLAN APO 5 x Observation

M PLAN APO 10 x Observation

M PLAN NIR 20 x Observation/laser processing

M PLAN NIR 50 x Observation/laser processing

Auto focus system

Focus Type:

Manual Focus

Shock Absorbers system

Shock form:

Gas pressure shock absorbers

Natural frequency (vertical / horizontal) :

2 ~ 2.3 Hz

Manufacturers supply specifications 4 ~ 6 kg / ? (Compressed or Nitrogen Gas)

(Floor earthquake Level of equipment need) :

B Grade

ATS LR2200M using in SEMI standard vibration spec V.C.B. as below .

Should meet the following condition even when operating surrounding equipments

Laser slit

Repair size:

7-65 inch

Spot repair:

Min: 3um * 3um

OS?

Windows system

HD?

500G*1

RAM?

2G

Language?

Simplified Chinese/English

Monitor?

19”monitor

Key board?

ATS-standard

Mouse?

ATS-standard

Operating mode

Software features

- (1) Laser Mode operation function

Provides Point / Line / Block three kinds of laser processing mode, the laser parameters of recipe, according to user teaching pre-patched path and type on the screen, for a one-time quick fixes after teaching.

- (2) Manually operated laser firing functionality

- (3) Recipe Archive feature

Provides information on laser parameters / substrate parameters Recipe Archive feature

(4) User login / logout (rights management)

(5) Up and down manually adjust the light source

(6) Up and down light coordinate each multiplying power setting automatically adjusts

(7) Basic measurement tools

(8) Image Archive feature

(9) The lens switches auto-correction feature

(10) Image parameter setting function

- brightness setting

- contrast setting

- saturation setting

- contrast setting

(11) Operating language selection

- Traditional Chinese/Simplified Chinese

- English

Utility Equipment

Power 3 phase / AC 220 V ± 10%, 30A

Power connector M6 terminal block

Ground wire JIS grade 1, 8mmsq above

Using environmental:

Temperature 20-26C

Humidity 30-70 %( No dew drop is allowed)

Clean level class 10,000

Warranty Period

12 months after acceptance provides warranty service (excluding consumption of spare)

Work efficiency

Staffing:

A group four people (according to standard workshop prevail

Personnel division:

1 screening, 2 people looking for point identification, one operate the machine

Tools needed:

2 optical microscopy

Personnel allocation:

1 person screening, 2 looking for point identification, one person operate the machine

Tools needed:

Optical microscopy 2 set

Repair the fault and the standard output (use 32-inch LCD panels as an example)

ITO failure:

1 line of 500 pieces, 3 lines or more of 400 pieces

Short circuit line:

Less than 3 lines of 350 pieces

Working hours:

Two work shifts, the average work of 8 Hour

Specific production according to worker skill level shall prevail

NOTE preparation ?

Different models in the control system and laser system parameter will be some relatively

changes ?specific programs can be noted in the customization process.