880SH Single Head Bonding Machine

- General Details

- Specification

- Accessories

- Inquiry

- Documents

- Related Products

MD-880SH Single Head Bonding Machine is designed for LCD/LED TV repair, which can solve the problem of ACF/COF/TAB fault, the function of MD-880SH is replacing, bonding, re-bonding COF/TAB on LCD glass and PCB .

The bonding machines includes below models:

- MD-880SH single head LCD repair bonding machine;

- MD-880DH double head LCD repair bonding machine;

- MD-815SH single head LCD repair bonding machine-Mini Version

- MD-816SH Single Head Bonding Machine-Mini Version

Which machine should I choose and what’s the difference of the two machine?

What is ACF/COF/TAB fault?

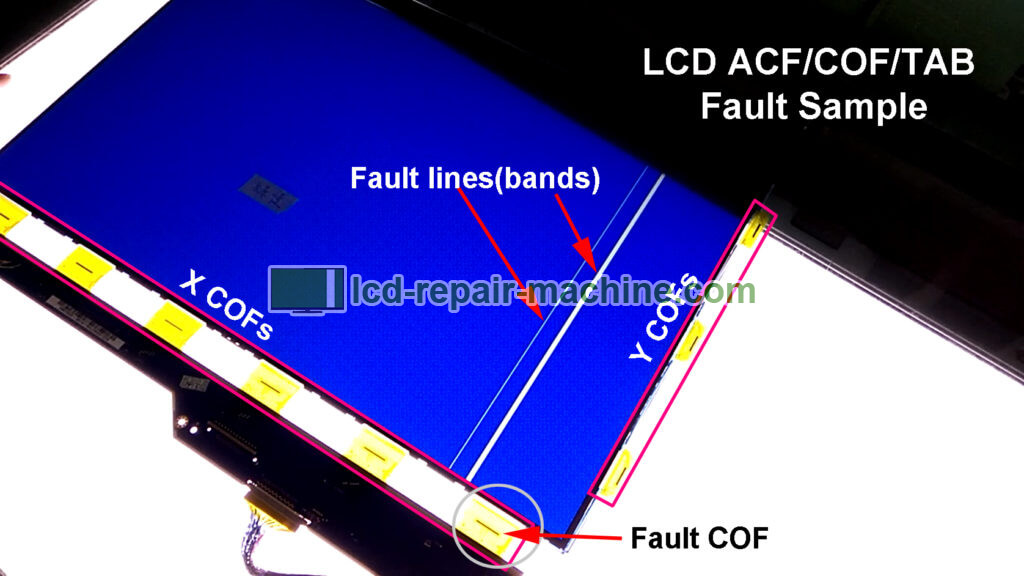

There is a picture below to show the ACF/COF/TAB fault of LCD TV.

There are some COFs/TABs to connect LCD glass and PCB boards, which called X COFs and Y COFs, some times vertical or horizon lines(bands) appeared on the LCD TV screen. On of the reason is the COF/TAB broken or disconnecting. In order to solve this problem, if the COF just disconnecting(not broken), use bonding machine to re-bond this COF; if the COF is broken(like chip broken), use bonding machine to replace it with a new COF.

What’s the payment and delivery time?

Payment: Terms EXW/FOB/CIF, by T/T, 100% deposit in advance (Recommend), Or 50% deposit and 50% paid before delivery

Delivery time: About one week.

How about the warranty?

Usually we provide 1 year standard warranty and whole life technical support.

How about the training?

We provide two training method: factory training and video training.

More detail please see here: Training

How you packing the machine when shipping?

LCD TV Repair Bonding Machine Package

How can I install the machine after I received?

Here is a video of MD-880SH disassembly procedure. You can refer to it and do the opposite procedure.?

MD-880SH Disassembly Procedure

LCD repair bonding machine introduction for repair LCD TV demo video?

Inquiry

MD-880SH Specification—–

Single Head Manual platform Automatic Pressure Machine

1) Equipment Model Number:

MD-880SH (Single Head)

2) Device Description :

Repair screen machine / Bonding machine

3) Device Uses :

FPC? COF?TAB? LCD Panel and PCB combination bonding

4) Applicable LCD panel specifications :

15″-65″

5) Applicable LCD panel thickness :

0.3MM-1.1MM[Single glass]

6) Bonding IC number :

Multiple / Panel Can be set

7) Bind direction :

X or Y Unidirection

8) Bonding IC size :

Replaceable blade according to IC specifications (The original machine is equipped 50X1.5X10)

9) Device processing time :

TFT?3.8S/chip

10) Production Beats :

TAB?100 pcs/H

11) Bonding Accuracy :

Within ± 1.5?m (support 4K screen)

12) Highest positioning accuracy setting :

±0.5?m (Currently domestic the highest index)

13) Equipment requirements the work environment :

Clean, No dust, Clean room

14) Supply Pressure :

0.5~0.7Mpa (Dry air source)

15) Power Supply :

AC 220V±10%?50HZ?1200W

16) Cylinder Device :

Japan SMC original thin cylinder MXS20-75/MXS20-100

17) Heating Type :

Pulse (rapid heating / cooling and auxiliary cooling function)

18) PID Temperature Control System :

Brand: Yamatake (C36TV0UA1200 model)

Adjustable heating curve Duty Cycle setting type

The peak temperature : within +/- 2 degrees Celsius

Room temperature time to 180 degrees the response time within 2-3 seconds

19) Hot pressing head :

Materials: Japan Titanium

origin: United States 50*1.4*10

Plane precision (hot press side) :0.001mm

Plane thickness 0.5 (Reserved 3 times grinding)

20) Thermocouple Type :

K type Original US OMEGA wire

21) Industrial control units / Programmer :

Import Panasonic PLC FX?C14T

22) Image unit :

Panasonic image processing system

COF counterpoint: down counterpoint

PCB counterpoint : have

Number of lenses : 2

Microscopy: 30-120 Continuous zoom

COF Display: 19-inch HD X2

PCB counterpoint the display : have

Upper light source : have

Down light source : have

23?COF trimming unit :

Origin: Taiwan

Rail Type: U-rail (2056 high)

Accuracy : 0.01

Adjustable direction :X/Y/R

R Itinerary : Coarse 360 degrees, fine tuning +/- 5 degrees

24?COF Fixture : COF mechanical clamping type, Z tilt radius micrometer trimming

25) Lens spinner unit :

Control mode: X / Y / Z micrometer control

Focus Adjustment: Manually adjust the focus

26) Position detection : None

27) Silicone / Teflon :

Manual switching position

28) LCD stage (platform) :

Manual sliding or fixed optional ,automatic stage can be customized

29) Alarm device :

Pressure abnormal/ temperature anomalies / thermocouple abnormal / action abnormal

30) Hot press head counterpoint :

Cylinder stop can be set at any position in the vertical direction

31) Control mode :

Touch screen + button operation Using Taiwan’s Wei Lun touch screen dual-core

32) Parameter setting :

According to the need to set up Store multiple sets of hot pressing parameters

33) Rated voltage :

180-220 (customizable 110V)

34) Peak power :

400-1100W (Supports 68X1.5X10 lengthened tool bit)

35) Maximum power :

1100W

36) Actual power :

580W

37) Body size :

1800X1200x1520mm(L*W*H)

38) Machine weight :

300KG

With MD-880SH, we provide the accessories below for free.

They are almost all the accessories needed by ACF/COF/TAB repairing, means no need buy other extra accessories.

| No. | Picture | Name | Model No. | Quantity | Unit | Specification | Remark |

| 1 |  |

Single Head Bonding Machine | MD-880SH | 1 | Set | Single Head | 2016Year |

| 2 |  |

ACF Anisotropic Conductive Film | AC-7206U-18 | 1 | Piece | 1.5X50M | Glass special |

| 3 |  |

ACF Anisotropic Conductive Film | AC-2056R-35 | 1 | Piece | 2.0X50M | PCB special |

| 4 |  |

Acetone Liquid | BT-H1 | 2 | Bottle | 500ML | |

| 5 |  |

Absolute Alcohol | CH3CH2OH | 2 | Bottle | 500ML | |

| 6 |  |

ACF Removing Liquid | G-450 | 1 | Bottle | 500ML | |

| 7 |  |

Hitachi Blue Glue | 1 | Bottle | 100ML | ||

| 8 | |

Fuji Silicone | 1 | Piece | 50M | ||

| 9 |  |

Teflon | 2 | Piece | 50M | ||

| 10 |  |

Heating Solder Iron | 1 | Piece | 30W | ||

| 11 |  |

Removing Wind Station | 825+Fan | 1 | Piece | ||

| 12 |  |

Alcohol Bottle | 3 | Bottle | |||

| 13 |  |

TAB Cutter | 1 | Piece | |||

| 14 |  |

Optical Microscope | 1 | Piece | |||

| 15 |  |

LCD Test Board | HXV59 | 1 | Piece | ||

| 16 |  |

Dial Test Indicator | 1 | Piece | |||

| 17 |  |

Allen key | 1 | Piece | |||

| 18 |  |

Air Compressor | OTS550 | 1 | Piece | Mute Oil-free | |

| 19 |  |

LVDS | Common Specification | 1 | Piece | ||

| 20 |  |

Cleanroom Wipers | 1 | Piece | |||

| 21 |  |

Cotton Swab | 1 | Piece | |||

| 22 |  |

Handheld Magnifier | 1 | Piece | |||

| 23 |  |

Precision Tweezers | Elbow? Straight | 2 | Piece | High Hardness Hyperfine | |

| 24 | Training | 4 | Days | Free Training |